The Significance Of High Quality Manufacturing And How Manufacturers Can Benefit

Quality in manufacturing is a very different idea to quality https://www.globalcloudteam.com/ in on a daily basis life. You would possibly consider a high quality television as one with the newest expertise, 8K OLED screens, with vivid and bright colour and dozens of in-built options. Quality is the most important factor in determining the long term success of the organizations. To obtain high quality, organizations may implement huge strategies like TQM principles, Lean manufacturing, Six Sigma, and Lean Six Sigma.

Using Quality Objectives To Define Quality Clearly

The manufacturing business was the primary to take a hard, scientific look at quality. You can’t afford product liability points that end result from sub-standard product. You also can’t afford inefficient processes.Producers use requirements and continuous process enchancment methodologies to improve both processes and product quality. High Quality is compliance to greatest identified standards, processes and specs. Manufacturing high quality may be outlined because the diploma to which a product or service meets or exceeds customer requirements and expectations. It encompasses varied factors similar to consistency, reliability, sturdiness, and performance.

The totality of features and traits of a services or products that bear on its capability to satisfy said or implied needs revolves around the customer. It is the flexibility of the material or element to carry out satisfactorily within the application for which it is intended by the person. High Quality of a product, thus, means conformance to customer’s requirements. A product is alleged to be of excellent definition of quality in manufacturing high quality if it satisfies the customer’s requirements when it comes to performance, grade, sturdiness, appearance, and meant use/purpose, etc. In order to hold water as an idea, “quality” has to account for tremendous differences in manufactured products. Features of high quality for, say, cutting-edge biologics, will differ from these for automobile elements.

Let say, it doesn’t meet our expectation which implies it is of unhealthy high quality. And ‘if it satisfies our requirement then it’s of good quality’. We should keep in mind that machine learning, regardless of the grade, the standard ought to be good.

- We ought to remember that, regardless of the grade, the standard ought to be good.

- Six Sigma is a data-driven method for course of improvement that aims to reduce defects and variations to attain near-perfect quality.

- Thus, in a position to improve productivity, profitability and achieve buyer satisfaction.

- As new ranges of high quality become attainable, understanding exactly what is meant by quality may help inform future efforts.

Outline High Quality: The Roots Of The Time Period

Matics aggregates and analyzes information from all machines, including these committed to quality control. Accurate, real-time high quality info is on the market through our intuitive platform, along with automated alerts and KPI monitoring to make sure that high quality points are resolved with minimal latency. Optimize product durability, performance, and reliability to satisfy or exceed customer expectations by integrating high quality engineering principles into design and production processes .

Elevate your team’s efficiency with our highest rated examine app, as evidenced by glowing consumer reviews. Empower your team to conduct inspections seamlessly, liberating them from tasks that don’t add value. Enjoy reduced error rates and enhanced collaboration across your workforce with our top-tier inspection resolution. Schedule a live, one-on-one demo with a product skilled and see how flowdit can help you go paperless and scale back expensive unplanned downtime.

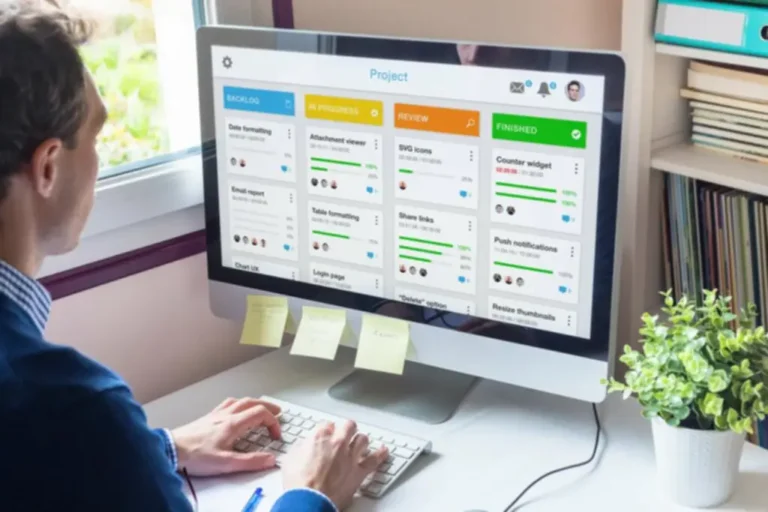

“Quality” is among the most necessary ideas in manufacturing. Each manufacturing facility ground has theoretical productivity that they could reach if every machine was available and operating at full velocity. However, manufacturing effectivity is affected by maintenance, logistics, and different factors, with high quality being among the many most necessary.

Outline Quality Across Totally Different Sectors

Six Sigma is a data-driven approach for course of enchancment that aims to scale back defects and variations to achieve near-perfect quality. It employs statistical analysis and problem-solving methodologies. When shoppers and partners see that you’ve taken the time to define quality clearly—and that your processes replicate that definition—they’re extra more doubtless to trust you. Trust results in repeat enterprise, stronger partnerships, and better word-of-mouth.

Whereas high quality control departments have traditionally offered technical assist for manufacturing high quality, producers have come to know that quality should be integrated all through the enterprise. In conclusion, quality administration is a crucial side of manufacturing that affects varied aspects of a enterprise. By understanding the significance of quality, implementing efficient high quality management techniques, and driving steady improvement, organisations can ensure excellence of their manufacturing processes. This commitment to quality can result in enhanced customer satisfaction, improved operational efficiency, cost reduction, and a competitive advantage available within the market.

The SPC method is used to measure the Process Capability of the production process. QA contains QC, but it emphasizes quality within the design of merchandise and processes. At the same time, producers do their greatest to scope the requirements of the consumer. A product that conforms to technical specifications but fails to meet the consumer’s want isn’t conforming to requirements.